Identifying the root causes of problems is crucial for achieving lasting solutions. That’s where the ‘5 Whys’ approach or technique in root cause analysis comes into play. By repeatedly asking “why?” to uncover the underlying factors behind an issue, this method enables businesses to tackle problems at their source. In this article, we’ll look closer into the power of the ‘5 Whys’ technique, share 5 whys examples and case studies, and explore how it can revolutionize your approach to root cause analysis.

The ‘5 Whys’ technique is a proven problem-solving method that originated at Toyota in the 1930s and has since gained popularity across industries worldwide. It involves digging beneath the surface-level symptoms to allow organizations to understand the true causes of their challenges, leading to more effective solutions and improved processes.

Whether you’re facing production bottlenecks, customer complaints, or recurring errors, the technique can help uncover underlying issues and implement long-lasting solutions. Join us as we explore the step-by-step process of applying this powerful methodology and unlock the potential for impactful problem-solving in your organization.

Understanding root cause analysis

Before we cover the ‘5 Whys’ technique, it’s important to understand the concept of root cause analysis. Root cause analysis is a systematic method for identifying the underlying causes of problems or incidents. It goes beyond the surface-level symptoms and addresses the fundamental issues contributing to these problems. Identifying and addressing the root causes helps organizations prevent issues from recurring and implement more effective solutions.

Traditional problem-solving approaches often focus on addressing symptoms rather than the underlying causes. This can result in temporary fixes that fail to address the core issues. Root cause analysis, on the other hand, provides a structured way to identify and address the root causes of problems, leading to more sustainable solutions.

ALSO READ: THE ULTIMATE ROOT CAUSE ANALYSIS GUIDE + TEMPLATE FOR EFFECTIVE PROBLEM-SOLVING

History and origins of the ‘5 Whys’ approach

The ‘5 Whys’ approach or technique is a problem-solving approach that originated at Toyota in the 1930s. It was developed by Taiichi Ohno, the father of the Toyota Production System, to uncover the root causes of manufacturing issues. The technique gained widespread recognition after it was adopted and popularized by Toyota.

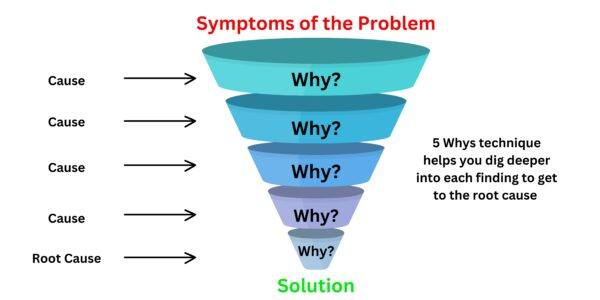

The concept behind the ‘5 Whys’ technique is simple yet powerful. It involves repeatedly asking “why?” to get to the heart of a problem. By asking this question multiple times, you can peel back the layers and uncover the underlying causes that contribute to the issue. This method helps to move beyond the immediate symptoms and delve into the deeper factors that are at play.

How does the ‘5 Whys’ approach work?

The ‘5 Whys’ approach is a straightforward process that can be applied to various business problems. Let’s walk through the step-by-step process of using this method:

- Define the problem: Start by defining the problem you want to address. This could be a recurring issue, a customer complaint, or a bottleneck in your production process. The key is to have a specific problem statement to focus on.

- Ask “why?” five times: Begin by asking “why?” to understand the immediate cause of the problem. Once you have the answer, ask “why?” to dig deeper into the underlying cause. Repeat this process five times or until you reach a point where the answer reveals an actionable root cause.

- Analyze the root cause: Once you have identified the root cause, analyze it to understand better why it contributes to the problem. This analysis will help you develop practical solutions that address the core issue.

- Implement corrective actions: Based on the insights gained from this analysis, develop and implement corrective actions to address the root cause. These actions should eliminate or mitigate the factors contributing to the problem.

Examples of successful applications of the ‘5 Whys’ approach

The ‘5 Whys’ technique has been successfully applied in various industries and organizations. Here are a few examples of how this method can be used to uncover root causes and drive impactful solutions:

5 Whys example 1: Manufacturing production bottleneck

A manufacturing company was experiencing a bottleneck in their production line, resulting in delays and decreased productivity. Applying the ‘5 Whys’ technique, they could identify that a malfunctioning machine caused the bottleneck. However, they didn’t stop there. They asked “why?” again and discovered that the machine malfunctioned due to inadequate maintenance. Further analysis revealed that the maintenance team was understaffed and lacked proper training. Armed with these insights, the company implemented a comprehensive maintenance plan, increased staffing levels, and provided training to the maintenance team. As a result, the bottleneck was resolved, and productivity significantly improved.

5 Whys example 2: Service company customer complaints

A service-oriented business was receiving multiple customer complaints about slow response times. Through the ‘5 Whys’ analysis, they discovered that the slow response times were due to a lack of standardized processes and communication gaps within the customer service department. Asking “why?” repeatedly helped the company identify the lack of standardized processes due to poor training and unclear guidelines. The organization then implemented a training program, established clear guidelines, and introduced a ticketing system to track customer inquiries. As a result, response times improved, and customer satisfaction increased.

5 Whys example 3: Software development recurring errors

A software development company faced recurring application errors, leading to customer dissatisfaction. Using the ‘5 Whys’ technique, they discovered that a lack of thorough testing caused the errors. Upon further analysis, they found the testing process was rushed due to tight deadlines. This insight prompted the organization to reevaluate its project timelines and allocate more time for testing. They also implemented a stricter quality assurance process to catch errors before reaching customers. As a result, errors significantly decreased, and customer trust in the company’s products improved.

These examples highlight the power of the ‘5 Whys’ technique in uncovering root causes and driving effective solutions. Organizations can address core issues and achieve lasting improvements by going beyond surface-level symptoms and delving into the underlying factors.

Implementing the ‘5 Whys’ in your organization

Now that you understand the ‘5 Whys’ technique and its potential benefits, you can implement it in your organization. Here are ten steps to get started:

- Create awareness: Introduce the ‘5 Whys’ technique to your team or organization. Explain the concept and its benefits for problem-solving and continuous improvement.

- Train your team: Provide training on conducting a ‘5 Whys’ analysis. Teach your team members the importance of repeatedly asking “why?” and guide them in digging deeper into the underlying causes of problems.

- Encourage a culture of curiosity: Foster a culture where asking “why?” is encouraged. Create an environment where team members feel comfortable challenging assumptions and exploring root causes.

- Document and track results: Establish a system to document ‘5 Whys’ analyses and track the results of implemented solutions. This will help you evaluate the effectiveness of your problem-solving efforts and identify improvement areas.

- Continuously improve: Use the insights from ‘5 Whys’ analyses to drive continuous improvement in your organization. Apply the lessons learned. Here are some steps to get started:

- Create awareness: Introduce the ‘5 Whys’ technique to your team or organization. Explain the concept and its benefits for problem-solving and continuous improvement.

- Train your team: Provide training on conducting a ‘5 Whys’ analysis. Teach your team members the importance of repeatedly asking “why?” and guide them in digging deeper into the underlying causes of problems.

- Encourage a culture of curiosity: Foster a culture where asking “why?” is encouraged. Create an environment where team members feel comfortable challenging assumptions and exploring root causes.

- Document and track results: Establish a system to document ‘5 Whys’ analyses and track the results of implemented solutions. This will help you evaluate the effectiveness of your problem-solving efforts and identify improvement areas.

- Continuously improve: Use the insights from this analysis to drive continuous improvement in your organization. Apply the lessons learned to prevent similar issues from recurring and enhance your processes.

Tip: The ‘5 Whys’ technique may not be suitable for all complex problems with multiple root causes. Consider combining it with other problem-solving methods in these situations to gain a more comprehensive understanding.

4 Tools and resources for conducting effective ‘5 Whys’ analysis

Several tools and resources are available to facilitate the ‘5 Whys’ analysis process. Here are a few that can assist you in conducting a practical root-cause analysis:

- Fishbone diagram: Also known as a cause-and-effect diagram, it helps visually identify possible causes and their interrelationships. It can be useful for organizing and structuring ‘5 Whys’ analyses.

- Root cause analysis software: Various software tools streamline the root cause analysis. These tools often provide templates, data visualization capabilities, and collaboration features to enhance the effectiveness of ‘5 Whys’ analyses.

- Training materials and workshops: Many organizations offer training materials and workshops on root cause analysis and the ‘5 Whys’ technique. These resources can provide in-depth guidance, case studies, and practical exercises to enhance your understanding and application of the method.

- Expert guidance: If you’re facing complex issues or need additional support, consider seeking expert guidance from consultants or professionals experienced in root cause analysis. Their expertise can help you navigate challenges and unlock the full potential of the ‘5 Whys’ technique.

Leveraging these tools and resources can enhance your ‘5 Whys’ analyses and drive more impactful problem-solving efforts.

Case studies showcasing the effectiveness of the ‘5 Whys’ technique

To further illustrate the effectiveness of the ‘5 Whys’ technique, let’s explore a few case studies that demonstrate its impact:

Case Study 1: A retail company’s stock shortages

A retail company was experiencing frequent stock shortages, leading to lost sales and dissatisfied customers. Using the ‘5 Whys’ technique, they discovered that delays in the supply chain caused stockouts. By repeatedly asking “why?” they identified the delays due to inaccurate demand forecasting. The company then implemented a more robust demand forecasting system, improved supplier communication, and streamlined inventory management processes. As a result, stock shortages significantly decreased, and customer satisfaction improved.

Case Study 2: A hospital’s medication errors

A hospital was facing an alarming number of medication errors, posing risks to patient safety. Through the ‘5 Whys’ analysis, they identified that the errors were caused by miscommunication between healthcare providers. By delving deeper, they found that the miscommunication stemmed from a lack of standardized protocols and inadequate training. The hospital implemented standardized protocols, improved communication channels, and provided training on medication safety. As a result, medication errors decreased, and patient safety improved.

These case studies highlight how the ‘5 Whys’ technique can uncover root causes and drive effective solutions in diverse industries and contexts.

- Remember, to effectively apply the ‘5 Whys’ technique, it’s crucial to create awareness, train your team, encourage a culture of curiosity, and continuously improve based on the insights gained.

- Be mindful of common challenges and pitfalls, and leverage tools and resources to enhance the effectiveness of your ‘5 Whys’ analyses.

ALSO ACCESS OUR ROOT CAUSE ANALYSIS TEMPLATE

Harnessing the power of the ‘5 Whys’ technique for continuous improvement

The ‘5 Whys’ technique is a powerful tool for root cause analysis that can revolutionize your approach to problem-solving. By repeatedly asking “why?” and digging beneath surface-level symptoms, organizations can uncover the underlying causes of problems and implement impactful solutions.

By unlocking the power of the ‘5 Whys’ technique, you can drive continuous improvement in your organization, tackle problems at their source, and achieve lasting solutions. Embrace this proven method for root cause analysis and unlock the path to a more efficient and effective business.